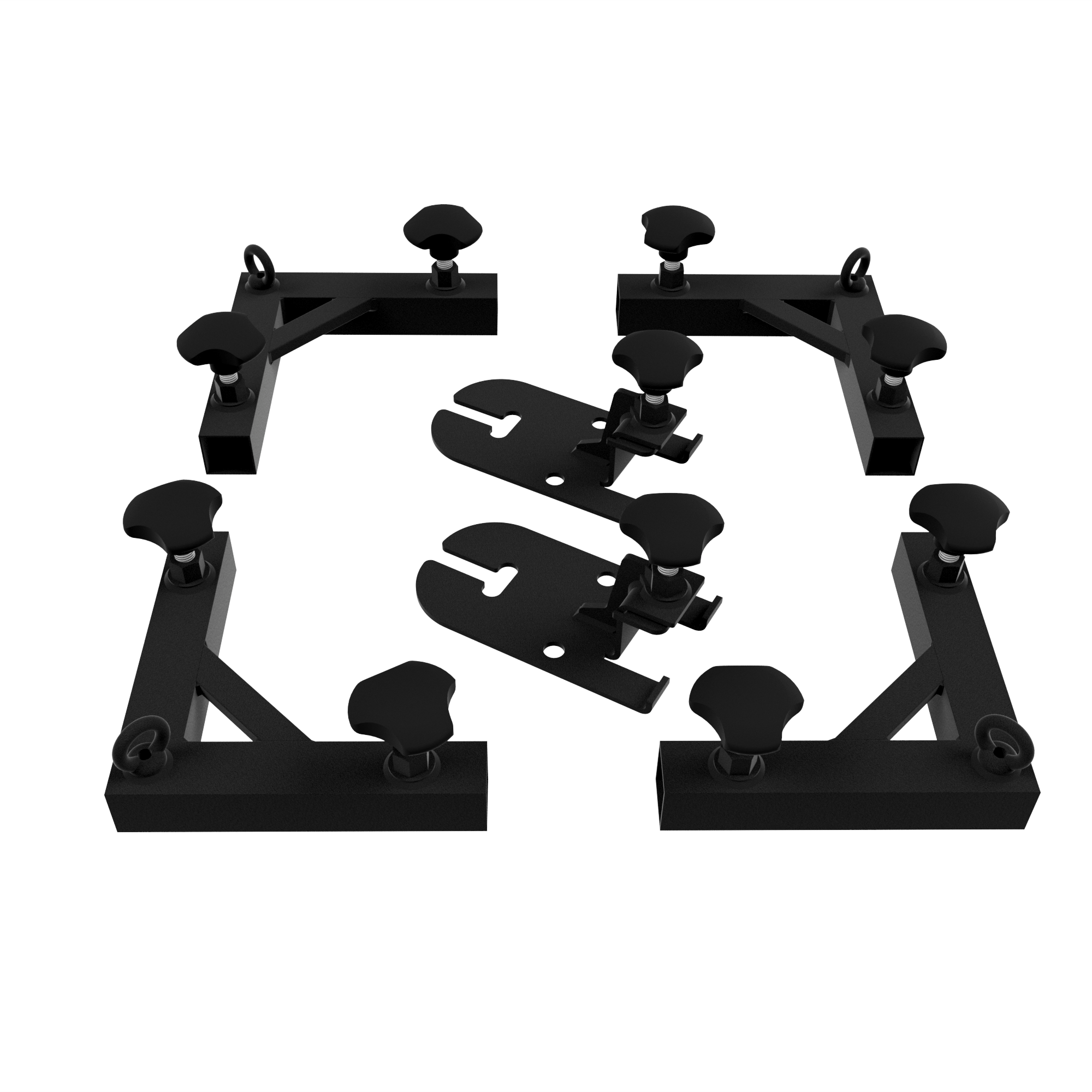

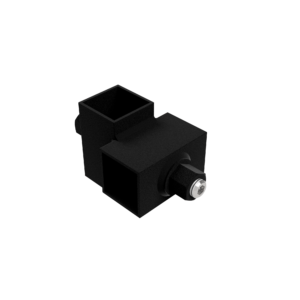

Overhead 90° Corner

Standard perpendicular connector with handy knobs for fast assembly and an eyelet for attaching the frame to the ceiling. Designed for butterfly/overhead frames. First in the Corner System family.

The entire system consists of 30 x 30 mm square aluminum tubes and 35 x 35 mm steel connectors. We introduced a range of different connecting elements, so any useful configuration is possible: frontal connection, 90º, 45º and 3-dimensional 90º for lightboxes. The aluminum tubes can also be connected to one another. All elements are by default powder painted black, for extra endurance and discreet look. We use stainless steel mounting elements, such as screws, pins, nuts and knobs to ensure the durability of our products. You will find a list of all the basic Corner System components at the bottom of this page.

We offer few different configurations – sets and kits, as we like to call them – matching the industry standards.

The kits are the 366 x 366 cm (12’ x 12’) overhead frame and 244 x 244 cm (8’ x 8’) butterfly frame, with the latter available with either quick release ears, or 16 mm pins. They have been designed to ensure stability and quick assembly. The frames are lightweight and durable.

Next we have sets of corners and connectors without the aluminum tubes, so you can use any 30 x 30 mm square tubes to match your conditions. Overhead/butterfly corners are available with either quick release ears, or 16 mm pins. We also offer a lightbox set consisting of 8 lightbox corners.

We understand that there are situations on a set where you need a very specific type of equipment, but not always have it, due to its weight, size or cost. So we decided to utilize the possibilities of the Corner System and introduced a series of custom elements, that allow you to quickly and reliably build jibs, custom frames, stands, etc. Save space and time – use our Corner System.

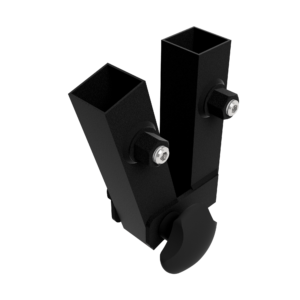

Highgly specific piece of equipment, used for mounting parallel frames at a constant separation of 305mm (12″). Double Ears come in handy whenever you need a stable setup with two frames at a given distance. Typical application is a LED panel and a diffusion. Thanks to the offset construction of the connecting part, the setup will be fully operatable and will only need two stands to support.

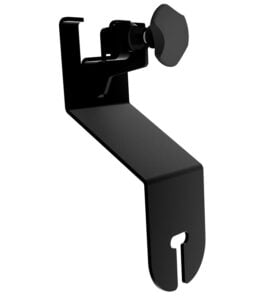

A more functional alternative to a standard quick release ear. The backdrop ear provides an offset from the grip head, so you can mount your frame in various positions and still have full operability. Durable steel construction is stiff enought to support most frames.

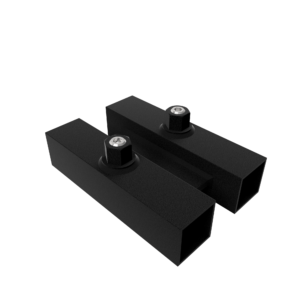

Provides a stable mounting point of a single tube to a flat surface, e.g. a wall or an apple box. The plate has two different sizes of holes, to match mounting screws to the load on the adapter. Can be used vertically or horizontally.

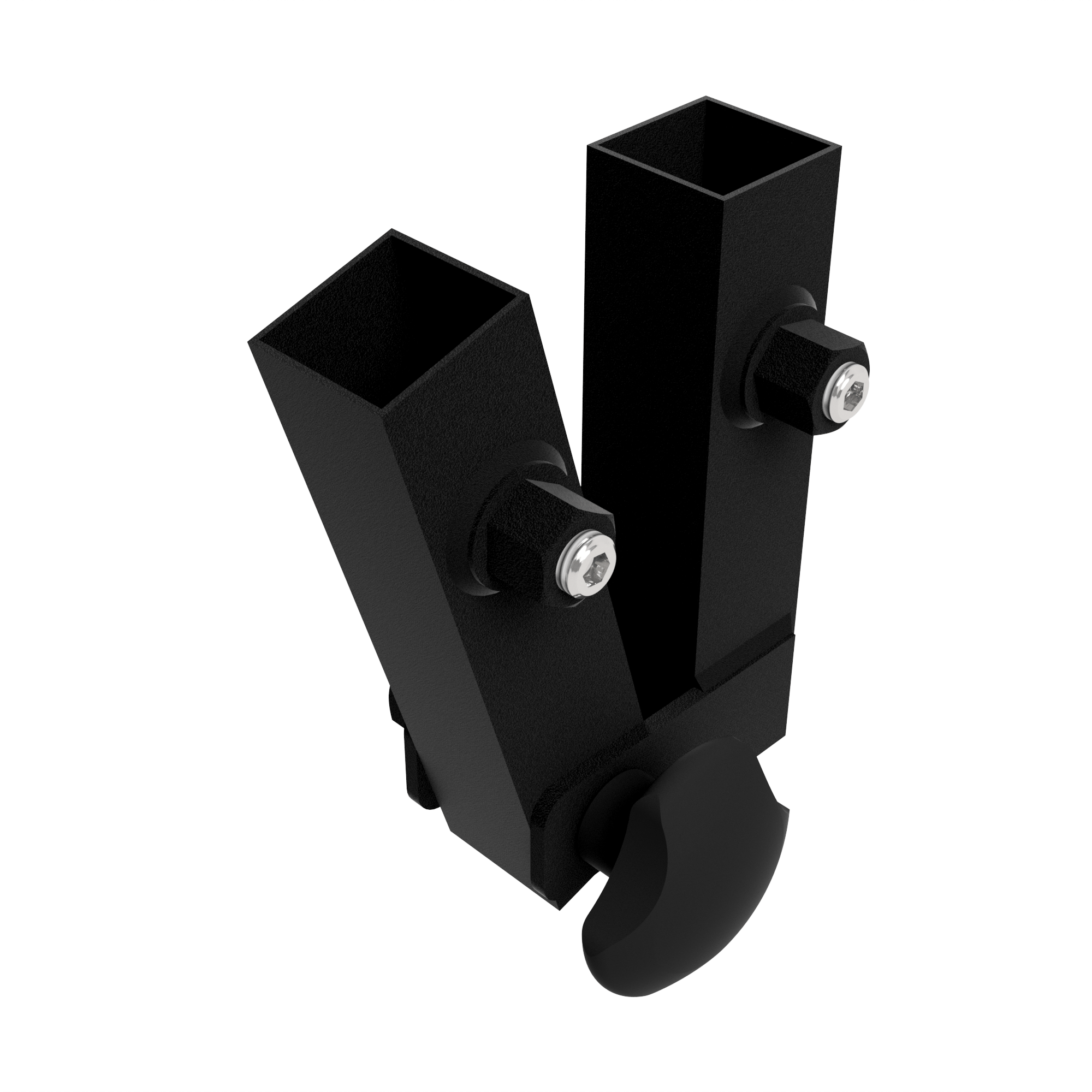

Connect two tubes parallel to each other to gain more stiffness. Useful for long, loaded constructions.

Allows to quickly build a so-called menace arm – stable jib for your lighting equipment – and mount it to a standard grip head. The centilever has a welded stainless eyelet to attach an extraction to.

Connect two tubes perpendicular to each other, at any desired lenght. Useful in building large, custom lightboxes – allows to quickly change the position of a bar.

Adjustable angle receiver and a handy knob make it a perfect component of a large construction. The connector can slide along a tube.

This element can be moved along a tube, to gain an extra mounting possibility in any point you like.

Sliding element wit a 16 mm pin. Provides a mounting point fo a lamp, etc. directly on the frame/construction you build. It can be moved along the tube.

Have a look at some of the available solutions.